How to Reduce Lead Time in Garment Manufacturing : “Time is money,” as they say, and this is never more true than when discussing lead times for manufacturing. Consumers want their purchases and deliveries to be made quickly, so knowing what lead-time is, how to cut it down, and how it affects the customer experience are all valuable contributions that can help you grow your company.

How to Reduce Lead Time in Garment Manufacturing

What is lead time in fashion?

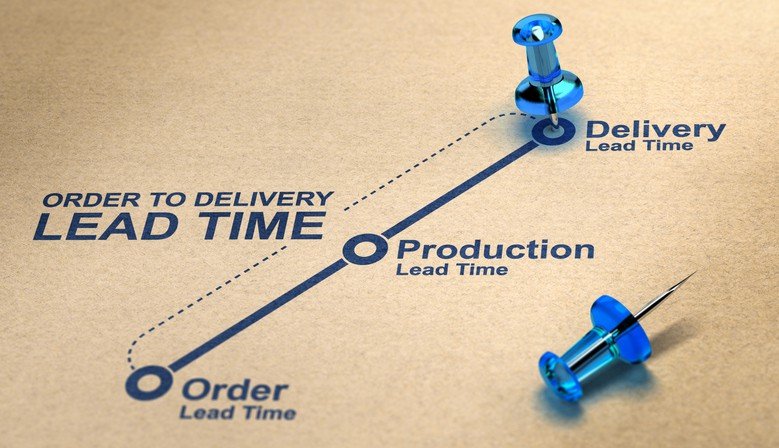

Lead time in the fashion industry refers to the total amount of time needed to finish the entire production process of a garment, from the placement of the order to the delivery of the product. This involves a lot of steps, including designing, dying, printing, cutting, sewing, quality checking, and shipping.

The time between placing an order and having the product delivered to the customer is known as the lead time in the garment manufacturing industry. Consumers want their purchases and deliveries to be made quickly, so knowing what lead time is, how to cut it down, and how it affects the customer experience are all valuable insights that can help you grow your company.

Why is a shorter lead time important?

Many companies now inquire as to whether they ought to make a concerted effort to shorten lead times.And the response is unquestionably yes. Although being aware of lead times is beneficial for carefully controlling inventory, our goal should always be to reduce the time spent on product development.

These are some of the causes. Increased adaptability in quickly evolving marketsBeat the oppositionFaster stock replenishment to prevent backorders and stockouts and possible decrease in carrying costs are but a few of the explanations for why you ought to be attempting to shorten Lead Time in Clothing Manufacturing.

Must Read: Private Label Clothing Manufacturers: Your Path to Quality Apparel

How to Reduce Lead Times in the Garment Manufacturing Industries:

In the clothing manufacturing industry, shorter lead times can increase productivity and customer satisfaction.

The following list of tips will help shorten Lead Time in Clothing Manufacturing.

1. Put lean manufacturing principles into practice:

The main goals of lean manufacturing are efficiency gains, lead time reduction, and waste elimination. Manufacturers can cut lead times, increase product quality, and increase overall operational efficiency by putting lean principles into practice.

2. Adoption of technology:

All the more successful businesses invest in technology such as computer-aided design (CAD) for pattern-making and cutting, 3D printing for prototypes and custom clothing items, fully implemented CAD (Computer Aided Design) and partially implemented CAM (Computer Aided Manufacturing).

Because CAD designs quickly for various sizes of the same design, it helps achieve shorter at times. By eliminating the need for manual material handling and achieving greater manufacturing speeds and accuracy, CAM also reduces manufacturing time.

Supply chain management is enhanced by the use of RFID (Radio-Frequency Identification) technology for inventory tracking and management. Generally, the need to cut costs and increase efficiency is what drives the adoption of new technologies in the clothing industry.

Must Read: Outfit Ideas To Go Out Partying In Summer

3. Put improvement processes into place:

Manufacturers can pinpoint the problems causing production delays by putting continuous improvement processes into place.We can examine production process data, find appropriate solutions, and put those solutions into action.

4. Shorten setup and changeover times:

These can be a significant cause of manufacturing delays. Reducing the amount of time it takes for production line changeovers requires careful planning regarding the number of machines, labour, fabric, and trims that are required.The setup time can be measured using SMED, a lean manufacturing technology.

5. Enhance production scheduling and planning:

Manufacturers can minimise delays and cut down on the time it takes to produce each product by using an accurate production plan. Every task is guaranteed to be finished on time and in the most effective order with precise planning and scheduling. By putting in place real-time monitoring systems, demand-driven production optimisation, supplier collaboration, and a continuous improvement programme, we can enhance the production process.

6. Enhance supply chain management:

Reducing delays in material sourcing may be made possible by improving supply chain management. The following are some ideas to enhance supply chain administration.

- Build a solid rapport with the supplier.

- Boost the visibility of the data.

- Make use of modern technology. streamlining of the route.

- Inventory control.

Must Read: Clothing Manufacturers India: From Tradition to Innovation

Concluding Remarks How to Reduce Lead Time in Garment Manufacturing

Efficiency and customer satisfaction in the apparel industry depend on an understanding of and ability to manage lead time. Careful consideration is needed for the various factors that affect lead time, including supplier location, product complexity, brand size, and fabrication techniques. Apparel Manufacturers should use technology, improve production planning, apply continuous improvement procedures, embrace lean manufacturing principles, and expedite setup and changeover times to cut lead times.

Furthermore, reducing delays is largely dependent on efficient supply chain management, which includes fostering solid relationships with suppliers and making use of technology.You can increase cells in many different ways by reducing your manufacturing time. You can also save money by optimising your inventory management and avoiding paying to carry stock that you don’t need.

It’s a win-win situation, but to make it work, you’ll need to recognise and manage your late periods.By putting these strategies into practice, Private label Clothing Manufacturers can meet market demands and increase operational efficiency, which will ultimately result in happy customers and profitable enterprises.

Must Read: India’s Top 10 Clothing Manufacturers